Mind the Edge: How to Select the Best Edging for Your Project

Advertisement

Whether your next rooftop project serves a functional role or includes an aesthetic component, selecting the right products is critical to creating a sustainable rooftop. Although much consideration is given to plant selection, soil type and depth, drainage features and hardscapes, a less talked about, but equally important component of a sustainable rooftop is the edging. Proper edging selection involves matching edging material and attributes to the specific requirements of the green rooftop application.

Clean separation and clear delineation with Geoedge on Royal York in New York, NY. Photo: Permaloc Corporation

The primary benefits of edging include better aesthetics, structural integrity and reduced cost. Edging improves aesthetics by maintaining a clean delineation between various depths of growing media and plants, stone drainage ways and pavers. In some applications, the edging serves as a visual component along raised planting areas. Structural integrity is accomplished by retaining pavers, ballast, and growing media in their original position. For green roofs, these living intersections are the most vulnerable to deterioration over time. Proper edging selection and placement will reduce the need for continual maintenance of these borders and thereby reduce long term maintenance cost.

There are many edging materials available to choose from, each with their own benefits and drawbacks. Aluminum provides the durability and long-term performance of a metal edging while being lightweight, easy to form and will not rust or corrode over time. Although the initial investment is generally higher than other materials, the long-term value makes it a preferred choice. Steel edgings are well known for their durability, however, excessive weight can add cost to handling and installation while corrosion and rust can impact both long term aesthetics and performance. Plastic edgings are lightweight and generally provide the lowest initial investment, however, they do not provide the long-term performance of metal edgings and may require higher maintenance cost over the life of the project. Wood can be used as a natural rooftop edging. Wood can add a visual appeal when desired, however regular maintenance is required to protect the finish while preventing rot, warping and infestation. Concrete is a durable edging solution for projects that can accommodate the additional weight and installation logistics.

Within each material category, all products are not created equal. Aluminum edgings are available in various thickness and features. Plastic edgings made from polyethylene versus polypropylene will have different performance characteristics. Likewise, wood species will have varying resistance to rot, warping and infestation. Hence, it is important to understand the advantages and drawbacks of each material relative to accomplishing your project goals.

Advertisement

Edging maintains the strong bold lines on 900 N Michigan in Chicago, IL. Photo: Permaloc Corporation

Layers are achievable with different height edgings on 900 N Michigan in Chicago, IL. Photo: Permaloc Corporation

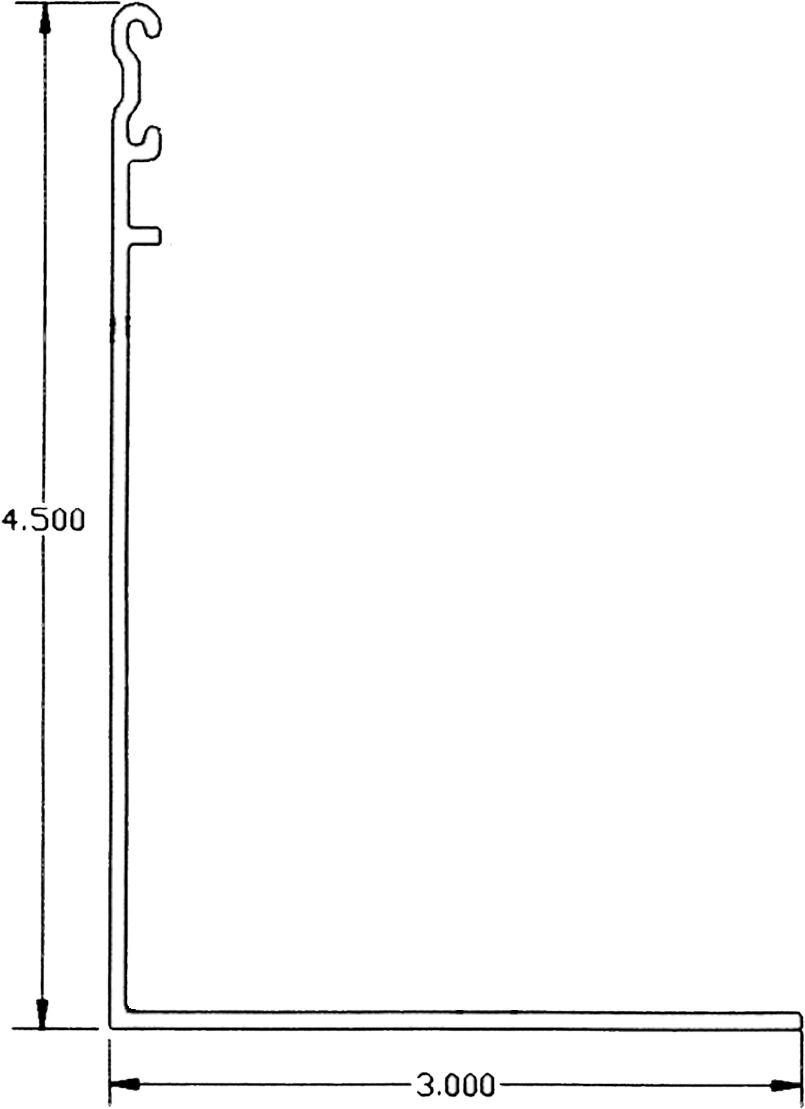

Beyond the material, consideration must also be given to the product attributes critical to rooftop applications. Drainage of rooftop projects can be impacted by the edging so the selected product must allow water to pass through to a drainage layer or drainage way to avoid pooling or water backups. Integrated connection systems ensure the edging stays aligned and eliminates joint separation which can lead to soil erosion. If your project calls for rectilinear lines, curvilinear lines, or both you will need to select an edging that can accommodate those requirements. Anchoring requirements for edging on rooftops are different from edgings at grade which typically use stakes or spikes to hold the edging in place. In order to protect the waterproof membrane, rooftop edgings are usually “L” shape utilizing adjacent material resting on the base to hold the edging in place. The base length should be suitable for the vertical wall and adjacent media. A textured base can provide additional grip to hold the edging in place. Products that are not specifically designed for rooftop applications rarely offer these attributes requiring additional labor or modification during installation.

Advertisement

Cross sectional diagram donstrating ballast of edging system. Photo: Permaloc Corporation

When you match your edging selection with your project requirements, consider performance, aesthetics, installation, availability and cost. The edging must perform based on your project requirements with the needed attributes and durability for the life of the project. Aesthetically the edging must match your application whether it is providing a visible/decorative role or a functional role where a narrow profile, less visible edge is preferred. Rooftop applications can add complexity to installation. Consider a product that is easy to handle and install that minimizes on the job modifications to reduce costs.

Availability is a factor because even the perfect product has no value if it’s not available when you need it. Like all products, cost is always part of the decision. Generally, rooftops have restricted access for personnel, tools, and equipment, so consider not only the initial investment but the long-term maintenance cost as well. As you navigate this process, partner with manufacturers with the expertise to understand your application and provide qualified assessments and product recommendations.

Selecting the right edging will ensure your next green rooftop project is functionally and aesthetically sustainable.

Philip Koops is President of Permaloc Corporation, a manufacturer of sustainable edgings solutions for the landscape, hardscape and green build markets. Philip has spent his career designing, manufacturing and marketing edgings found on prestigious projects around the world.