The Development of Skyland USA and Its Green Roofs Legacy

Advertisement

The production yard at Lauren Valley Soils. Photo: Skyland USA

Skyland USA was founded in 2005. It’s hard to believe it’s been almost 20 years since we started producing our rooflite green roof soil products.

Before we officially founded the company, we tentatively took our first steps into the green roof industry. It started with Ed Snodgrass of Green Roof Plants. In 2002, he was beginning to grow different varieties of green roof plants and wanted a "green roof” soil.

At the time, I was working at Laurel Valley Soils, and we were used to creating soil mixes for various at-grade projects, but we hadn’t considered or even really heard much about green roof soil.

At the time, neither Ed nor I knew much about green roof soil, but we both did a bit of research and came up with a blend. It wasn’t the best blend, but it worked for a year or two for a few initial green roof projects.

In the early days, we had to be so focused on the weight of the growing media. There weren’t many green roofs being installed, and the ones that were getting installed were often on retrofits, which meant that saturated weight was extremely critical. Almost no one was installing green roofs on new construction, so we had to constantly worry about the weight of our growing medium to be sure it could work on loading capacity constrained retrofits.

In 2002, we produced and supplied 25,000 square feet of green roof soil for projects that whole year. Each year, we got a bit busier in providing green roof soil to a few more projects.

A funny story about our first “big” order, which was a whopping 80 cubic yards! Our green roof soil was a blend of 80% lightweight aggregate and 20% organic matter, so we mixed 64 cubic yards of the lightweight aggregate with 16 cubic yards of our compost to produce those 80 cubic yards of finished material. We shipped it off to the customer, and as you might guess, the customer called the next day saying that we had shorted them. What we learned was that the compost we added filled the void space between the lightweight aggregate, and in the end, we ended up only shipping 65-70 yards of green roof soil. We never made that mistake again!

We founded Skyland USA in 2005, and we were very fortunate to have Peter Phillippi, MLA, and European green roof expert join Skyland that year.

Peter started a green roof design and build company in 1983 when he lived in Germany, and in 2004, he came to the US and was involved in several green roof pilot projects here. When he joined Skyland, he came to us with over 25 years of experience in the green roof industry.

Advertisement

Not only did he have experience in green roof projects and various innovations, Peter also played a part in developing the German FLL Green Roofing Guidelines, which are the state-of-the-art guidelines for green roof construction worldwide. Our test methods and performance standards are still governed by the FLL, backed by decades of testing, research and development in the field.

Having Peter join Skyland was an early game changer for us. His technical expertise related to green roof soil was based on long-term experience in the design, specification, construction, and maintenance of green roofs. He also had vast experience in all the technical requirements of a complex green roof project, which was critical to helping us develop soil solutions that worked for different projects. Peter truly gave us a head start to start providing the soil innovations the US green roof industry needed.

In 2006, we provided growing medium for our first New York City green roof project. It was a sedum meadow on top of a West Village apartment building. The project was featured in the New York Times and National Geographic because it was such a novelty at the time. It was a big project for us, and it helped create some momentum for our company.

2011 was an important year for the company and for the green roof industry as a whole. That’s the year that the United States passed the green infrastructure bill, which encouraged the research, development, and promotion of green infrastructure. That bill helped drive all green infrastructure, including green roofs.

The rooftop farm at Brooklyn grange which produces hundreds of pounds of produce. Photo: Skyland USA

At that time, we were steadily doing more green roof projects but we were still at a relatively low level of production. But after the bill passed, we had a growth spurt of close to 50%. From there, we have never looked back.

For the first 10 years or so, we mostly provided growing medium for extensive roofs. In 2014, though, we had a unique challenge come up. We were approached by a group of people wanting to put a rooftop farm on a building in Brooklyn, which would eventually become the Brooklyn Grange Farm. So we got to work to see if we could come up with a soil blend that could be used to grow crops. After a lot of work and fine-tuning, we launched our rooflite agricultural product.

It was designed specifically to grow rooftop crops and to function as a green roof media and all that entails, including weight requirements, water retention and drainage, and support for healthy plant growth. It was an important milestone for us because we were able to create a system with a deeper growing medium build-up that fit all the technical requirements and was able to support the farm plants.

It was also a moment when it felt like the industry was going to shift a bit from the extensive sedum-based green roofs we’d been doing to something different. We weren’t exactly sure what it would be, but we knew more demanding green roof applications were on the horizon.

Advertisement

A closer look at the Brooklyn Grange farm. Photo: Skyland USA

By 2014, we had installed over 10 million square feet of our green roof soil on projects across the country. During that time, we worked hard on the infrastructure part of it. We knew that in order to grow the way we wanted, we needed to be able to get our products anywhere in the U.S.

That’s when we realized we were going to have to find soil facilities that we could partner with to meet that nationwide distribution goal. This is when our blender network was born. We found top-notch soil facilities at strategic locations throughout the country that could handle blending our green roof soil mixes and delivering them to regional projects. It was a big deal then and is still a big deal now.

Our regional blenders offer all our rooflite soil products, which are sourced, produced and shipped within their region. The specific blends in each region are based on cost-effective raw materials and regional climate conditions. They help us cost-effectively meet the demands of green roofs in every corner of the country.

The rooflite intensive base product. Photo: Skyland USA

Around this time, we also really focused on helping designers and landscape architects figure out how much soil they needed for their green roof projects. It seems straightforward, but it’s not because of compaction. Basically, compaction is the change in the air or space between soil particles as it’s transported, installed, and when it’s exposed to the elements.

We developed an open source method to calculate compaction so people could order the right amount of growing medium. We didn’t want people to find they didn’t have enough soil as they moved through the shipping and installation process due to compaction. It was a customer-focused effort to make life easier for designers and installers, and it’s something we’re really proud to have done.

We were also working on a product to support those deeper green roof projects that we had an inkling were coming our way after the Brooklyn Grange Farm project. We were pushed to complete an intensive green roof development for a Children’s Hospital in Philadelphia in 2015. The plan called for a variety of plants, including trees, grass, and a variety of flowers and plants.

Advertisement

The green roof at the children's hospital in Philadelphia. Photo: Skyland USA

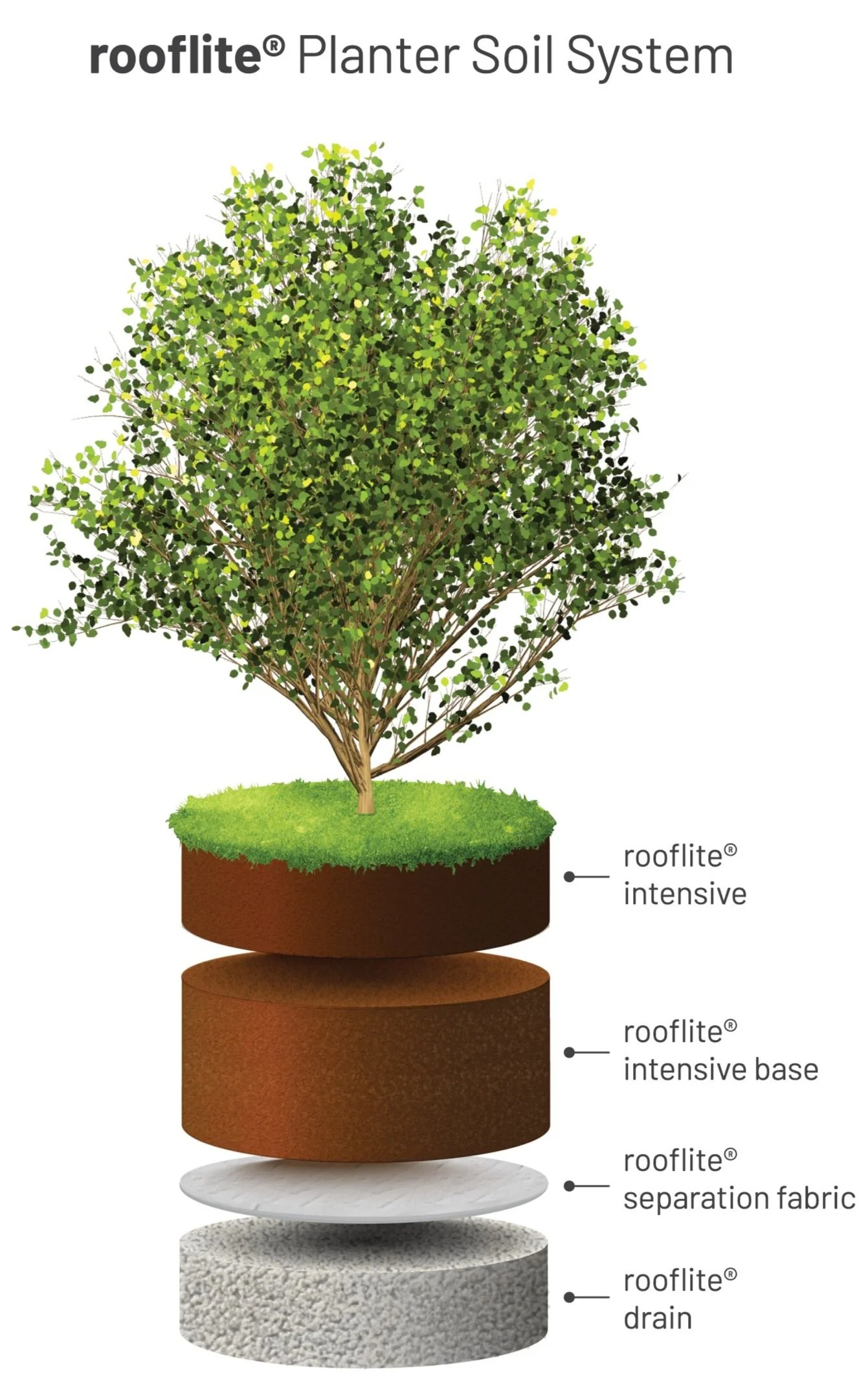

This is when our rooflite intensive base product was born. This product is an underlying layer that mimics and improves upon natural soil horizons while also being lightweight and free draining.

It was a turning point for us. Right around this time, there was a subtle shift in the industry, and we were seeing more projects that called for accessible green roofs with a variety of spaces that people could enjoy.

A three-part planter soil system. Photo: Skyland USA

Our intensive base product opened up so many possibilities on the design side to install too much greater depths with much more freedom and flexibility in the plant palette. Offering this product allowed us to provide our green roof soil for more and more projects. It’s the greatest innovation we’ve had in our company, and it’s still one of our most popular products.

Building on that, we started offering a three-part soil system, which turned into our Planter Soil System. This was another breakthrough that changed things for us. This system lets designers install planters, which can be expensive and technically complex. It’s specifically designed for the planter environment with its limited root space. By that time, we had a solid track record of providing quality green roof soil, so we had a lot of designers look to us for a planter solution. These days this three-part deep Planter Soil System is our most popular system.

Along the way, we did a lot of things that helped us keep growing. We brought on international blenders in Mexico, Chile, and Australia, which opened up whole new markets for us. We also created regional specifications for all our green roof soil products, so customers could get specifications for the region where their project was. We created CAD drawings to help with the design and planning process. It was all with the goal to help our customers design the kind of green roofs they wanted with our products.

As of 2023, we’ve installed 30 million square feet of our rooflite soil products. When we installed 25,000 square feet in 2002, I’m not sure I would have believed that we would make it to 30 million square feet, but we have.

It’s a testament to a lot of things, but first and foremost, our staff. We’ve been so lucky to have talented, dedicated people to help us grow along the way. One thing we’ve always done from the beginning is focus on sales. Sales were paramount for everyone in our company, regardless of an individual person’s role. The sales helped us grow, spurred us to innovate, and put us on the map.

We also have to give a nod to our green roof partners, who are constantly pushing us to create new products to meet their needs in designing and installing green roofs. Without their inspiration, we definitely would not have grown in the leaps and bounds we did over the past 20 years.

It’s been a fun and exhilarating ride, and it’s been so fun to see the green roof industry start with tiny little projects in small pockets of the country to the established and dynamic industry it is today. I can’t wait to see where our company and the industry goes next.

Advertisement

Joe DiNorscia is the president of Skyland USA. Learn more about rooflite here.